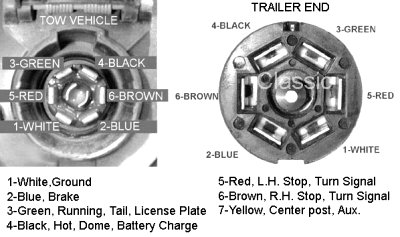

Trailer Wiring Codes |

|||

Terminal # |

Wire Color |

Gauge |

Circuit |

1 |

White |

10 |

Common Ground |

2 |

Blue |

12 |

Electric Brakes |

3 |

Green |

14 |

Tail, License, Running Lights |

4 |

Black |

10 |

Battery Charge (Hot) |

5 |

Red |

14 |

Left Turn |

6 |

Brown |

14 |

Right Turn |

7 |

Yellow |

14 |

Auxiliary (Back-up Lights) |